DDMRP: The solution for an agile supply chain and mastering market volatility

In a world defined by speed and adaptability, key determinants of success, businesses are in constant search for solutions to enhance the efficiency and flexibility of their supply chain. In this context, the DDMRP (Demand Driven Material Requirements Planning) method emerges as an innovative and robust strategy, providing an effective response to the unpredictable variations in demand and supply. This article aims to explore the foundations of DDMRP and demonstrate how this approach can transform supply chains into dynamic and resilient systems, capable of adapting in real time to the fluctuating demands of the market.

DDMRP Method: An Introduction

DDMRP is an approach to material resource planning that focuses on actual demand rather than traditional, often uncertain forecasts. It leverages principles from lean manufacturing, Just-In-Time (JIT), and the theory of constraints, thus creating a more reactive and agile system. Unlike traditional MRP approaches that rely on forecasts and static production schedules to plan production and purchasing, DDMRP uses real demand signals to guide these activities, allowing businesses to quickly adjust to demand changes while minimizing excess inventory. This adaptability makes supply chains more flexible and resilient, thereby improving operational efficiency and resilience.

The Fundamental Pillars of DDMRP

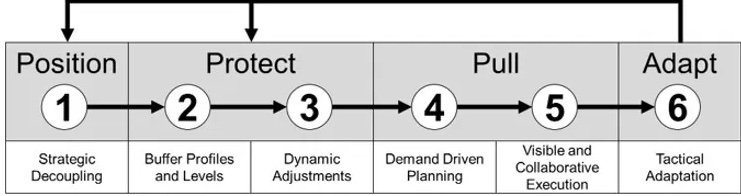

Strategic Decoupling: Establishing control points within the chain to manage demand and supply, aiming to reduce demand signal distortion and ensure smooth order execution.

Buffer Profiles and Levels: Defining profiles based on the attributes of items such as lead time and demand variability to appropriately calibrate stock levels.

Dynamic Buffer Adjustment: Adjusting buffer stock levels in response to changes in demand, lead times, and known or planned events such as promotional activities or seasonal variations, often using automation.

Demand-Driven Planning: Utilizing specific rules to trigger supply orders based on current market conditions, promoting production that directly responds to actual demand.

Visible and Collaborative Flow Execution: Clearly separating planning from execution, while managing orders based on alerts that indicate potential delays or stock integrity issues.

Tactical Adjustment: Adjusting the DDMRP model based on past performance and anticipated future events to maintain effective implementation, relying on a demand-driven sales and operations planning approach.

These foundational principles transform businesses into more reactive entities, less dependent on forecasts and conducive to creating robust and resilient supply chains.

Advantages and Challenges of Implementing DDMRP

Adopting DDMRP offers unmatched flexibility to businesses facing market uncertainties. Through its dynamic stock adjustment mechanisms based on real demand, companies can respond more effectively to demand fluctuations, reducing the risks of stockouts or overstocking. This agility translates into improved customer satisfaction and optimized operational costs.

However, implementing DDMRP is not without challenges. It requires cultural adaptation and a deep understanding of its principles. Resistance to change and integration with existing information systems are among the major obstacles. Overcoming these challenges is crucial, necessitating investment in team training and promoting effective communication of benefits at all organizational levels.

Conclusion

Ultimately, DDMRP proves to be a strategic approach for businesses looking to optimize their supply chain in response to current market challenges. By combining demand-driven planning with flexible and responsive stock management, it offers a robust solution to volatility and uncertainty. Despite the challenges associated with its adoption, the benefits in terms of reactivity, cost reduction, and improved customer satisfaction are clear, prompting businesses to consider DDMRP as an essential strategic lever in today's digital economy.

Take Action - Join Our DDMRP Training

Ready to elevate your supply chain to new heights of responsiveness and efficiency? Our DDMRP training is designed for professionals seeking to master the nuances of demand-driven planning and transform their operations into models of flexibility and resilience.

Don't let today's market complexity slow your success. Register now for our training program and start building a dynamic supply chain that not only meets current challenges but also anticipates and adapts to future needs. Our experts will guide you through each pillar of DDMRP, equipping you with the skills and tools necessary to implement this revolutionary methodology within your business.

Spaces are limited—to ensure a personalized and interactive learning experience. Secure yours today and take a decisive step towards operational excellence.

Register Now and Transform Your Supply Chain

Join industry leaders who have already taken the step towards an optimized, future-oriented supply chain management.

Let's advance your business together.